Plant Features:

1. Plant design is compact, need less space, height, manufactured using minimum structure with good factor of safety easy to run and maintain energy efficient.

2. Plant capacity 7-8 MT/hr on 5mm Pellet size.

3. Total power required =385 HP (Approx).

4. Designed with expandable capacity measures in future.

5. Plant is designed to operate & maintain easily.

6. In case of automation failure, provision of manual operation or by pass is provided.

7. Minimum Power consumption, Latest technology, recovers investment very shortly.

Hammer Mill

Double shaft Paddle Mixer

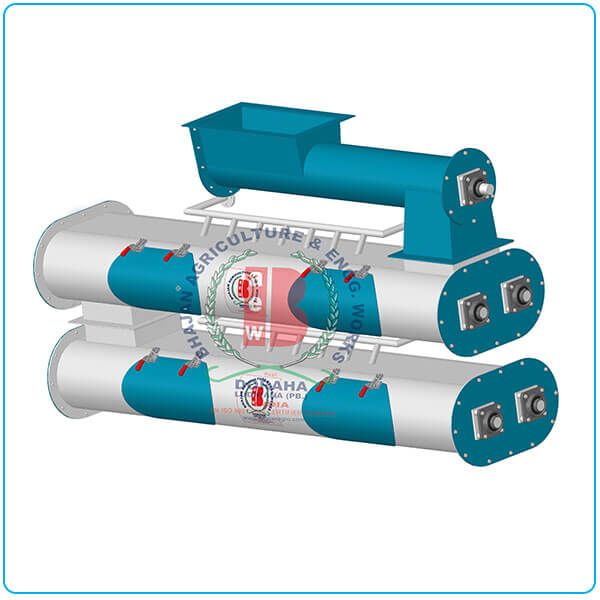

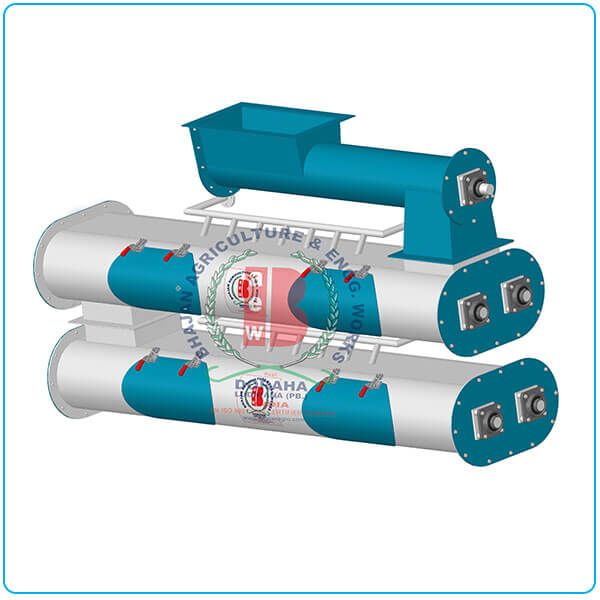

Conditioners

Pellet Mill

Cooler

Vibro

Crumbler

Auto- Bagging Machine

Machines Features:

Grinding: Our Standard Hammer mill is provided in this plant which runs on 80-100 H.P. Power. This machine is equipped with interlock sieve pressing system which makes changing sieves very easy & quick. VFD Controlled Rotary van feeder controls the material load with respect to main motor of hammer mill.

Mixing: Mixer is also known as the heart of a feed plant. Our latest Double shaft Paddle mixer Model BAEW-TSPM-10 (1 ton/batch) is provided in this plant, which ensures mixing efficiency CV < 5% in just 2-3 minutes. A homogeneous mixture is achieved in very short span of time. It saves the time & consumes less energy.

Conditioning: Stainless steel Double shaft conditioner [2Nos.] is used to achieve good conditioning which results in low power consumption of pellet machine.

Pelleting: Pellet mill model BAEW-PM 520 used to achieve 7-8 MT/hr on 5 mm hole Die [Stainless steel] & unique

Cooling: Counter flow cooler [Stainless Steel] with stationary product distributor for uniformly cooling of hot pellets, I.D. Fan with Dynamically balanced rotor & product level sensors.

Crumbling: Latest designed Crumblers are used in our plants in which Crumbler is equipped with rotary distributor; direct by pass Shute & Gap adjustable crumbling rolls. Very less fines re-circulate during operation.

Screening Latest designed screener is used for best screening results with zero breakdowns due to vibration.

Bagging: Bagging is manually done. Provision for automatic bagging is already there for future.